My "Magnetic Loop" project. (Started in dec 2008)

Many hams are using a "magnetic loop" antenna.

So I got curious and started collecting information about this antenna. The Internet is a great source.

After some calculations with "loopcalculator.xls" I decided to go for a 1.8 - 7 Mc loop capable to run 100 Watts.

A loop with a diameter of 400 cm is the goal.

The Loop calculator showed me I needed a vacuum variable capacitor of 25-600 pF/5KV.

On Ebay I found my cap... 15/750 pF - 5KV 15 meter, 22mm copper tubing was ordered...

January 2009...

I want the copper tube to be a

perfect loop so I made a simple tool:

Then I started with the motor drive, 4mm spindle to control the slide-pot meter and the end-switches.

febr-mrt 2009...

Lucky I have a metal lathe...

Lucky I have a metal lathe...

May 2009....

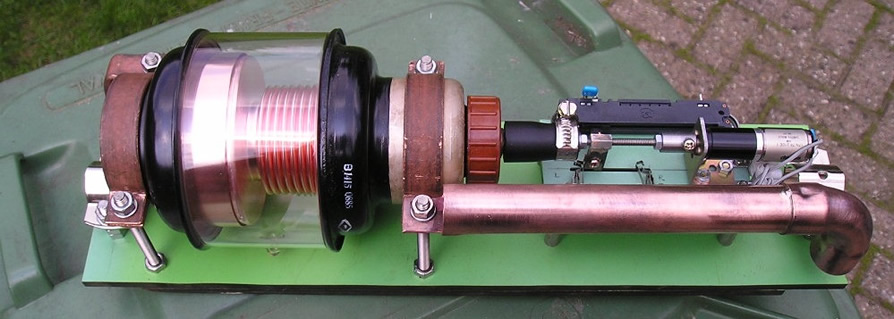

Here some pictures of the whole assembly. As isolator (and for alignment) I used a piece of rubber tubing.

(See the clamp on the rubber tubing to hold it on the drive-shaft. The rubber tubing fits tightly on the cap so

I don't need a

clamp and it works like a friction link in case the end-stop micro-switches mal function.

Looks good doesn't it!

All copper pieces are put together by brazing.

The green plate I used is Trespa (a strong kind of Pertinax), 8 mm thick.

All bolts, nuts and washers are Inox.

I need 4 wires for control of this unit. 2 for the DC-motor (turning left or right) and 2 for the potmeter.

Next thing to do is bending (rolling) the 22mm copper pipe and the cap-unit enclosure is to be made.

To be continued...... PA0KV

May 10, 2009

Bending the copper tube.

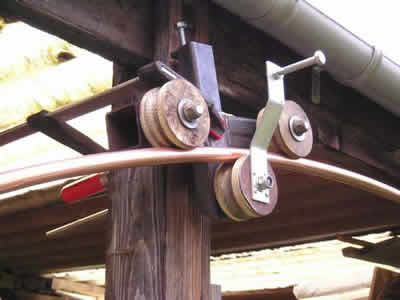

The intention was to push the tube between the three wheels

and adjust the middle wheel bit by bit

until the wanted radius is reached.

But the copper tube did not want to be pushed around.

So I had to change

the bending tool. I added a little swing handle.

First I drew a half circle with a 4 meter radius on the ground. Some crepe tape made the pencil drawing more visible.

The bending tool had to be mounted high enough for the

tube to hang freely.

Little swing arm.

Little swing arm.

A perfect fit!

The complete loop with vacuum cap assembly.

How do you mount a 4 meter loop vertically?

I choose for a Y-joint and some 36mm surplus epoxy tubing

(military tent sticks) which are 120 cm long and can be stacked together. I glued them with two-component polyester.

A Y-joint made from Inox tubing.

A Y-joint made from Inox tubing.

The whole assembly.

The whole assembly.

Loop is fed by a gamma match.

Loop is fed by a gamma match.

Picture speaks for itself. (80m)

Picture speaks for itself. (80m)

>> Part 2