After school I started working for the Philips company. We build machines for the production of parts for consumer electronics.

Color TV parts in particular. (Deflection units and HV transformers.)

Later I got the job of trouble shooter electronic maintenance on these production machines.

In the meantime I continued to study electronics and took various courses on micropocessors and microcomputers.

And slowly I entered the digital world.

Production machines got computerized and I studied 'computing & control' learning assembly languages. I was 27 when Philips gave my the opportunity to retrain, to become an IT / ICT specialist. A full year day school at Eindhoven University of Technology. After that I was offered an internship at Philips EDP (electronic data processing), the computer center of Philips.

Later they offered me a permanent job as systems programmer IBM mainframe computers. (VM/SP, VM/SP HPO, VM/MA, VM/XA & VM/ESA).

Great time!

Later, at 38, I started with the Ericsson company as IBM mainframe systems programmer.

There I also did install&maintenance of SAP, Unix, Java and mainframe / Unix networking.

I remember the moment I got the first TCP/IP connection, between our mainframe(IBM) and a Unix system, up and running. Hi.:-)

Internet did not exist jet!

Great time, but I kept my interest in electronics and combined it with my software skills.

There is so much that I have build (and programmed) over the years.. a fraction of it on this web site.

See "Projects" above in the header.

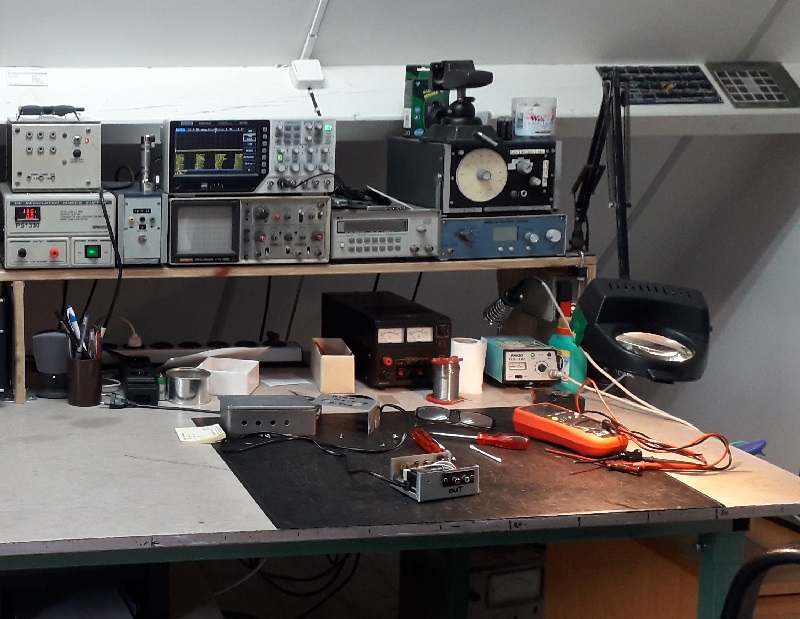

My 'workshop'....(till 8-2019) Eimac 3-500Z

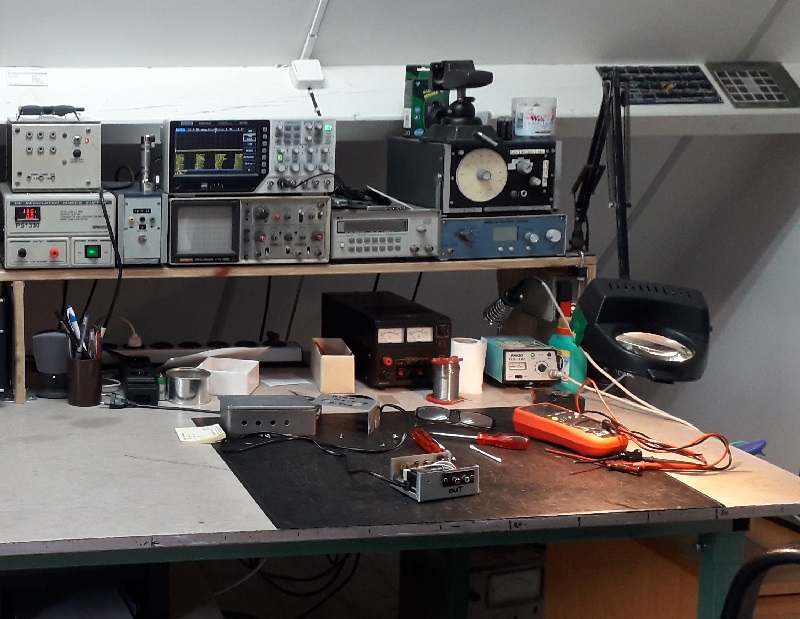

Current workshop (2021)